Blue Hydrogen vs Green Hydrogen: Everything You Need to Know

17 Jul, 202413 minsAs the world pivots towards renewable energy solutions, hydrogen stands as one of the frontr...

As the world pivots towards renewable energy solutions, hydrogen stands as one of the frontrunners, with blue hydrogen vs green hydrogen leading the charge. This guide explores the nuances of these two hydrogen production methods, shedding light on their processes, benefits, drawbacks, and potential roles in the global energy transition.

If you’re considering a career within this space, this guide will provide you with everything you need to know regarding the intricacies of green and blue hydrogen.

In this guide, we’ll explore:

- What is blue hydrogen?

- How is blue hydrogen produced?

- The benefits of blue hydrogen - how it’s utilised

- The drawbacks of blue hydrogen

- What is green hydrogen?

- How is green hydrogen produced?

- The benefits of green hydrogen - how it’s utilised

- The drawbacks of green hydrogen

- Blue hydrogen vs green hydrogen: Summarising the differences

What is blue hydrogen?

Blue hydrogen stems from steam methane reforming (SMR) and is heavily combined with carbon capture and storage (CCS).

Primarily derived from natural gas, composed mainly of methane, blue hydrogen production is created when methane is reacted with steam (H2O) at high temperatures to form a chemical reaction. The result of this reaction ultimately produces two byproducts:

Hydrogen Gas (H2): The central product engineers strive to achieve through this process is hydrogen, a clean-burning fuel with various potential uses.

Carbon Dioxide (CO2): Carbon dioxide is another byproduct of blue hydrogen production. This chemical compound is a greenhouse gas, making it a drawback of the blue hydrogen production process.

While blue hydrogen is a low-carbon energy source, it's not entirely carbon-free. However, blue hydrogen jobs today focus on a commitment to environmental responsibility through carbon capture and storage. Instead of releasing CO2 into the atmosphere, the CO2 emissions from blue hydrogen production are immediately captured. Once captured, this CO2 is securely stored or repurposed, effectively mitigating its environmental impact.

How is blue hydrogen produced?

To delve deeper into the steps you could be involved in by pursuing a career in this niche. Here are the intricacies of how blue hydrogen is produced:

- Feedstock - natural gas:

Blue hydrogen production begins with natural gas, primarily comprised of the abundant fossil fuel of methane. Here, methane serves as the foundational feedstock for the production process. - Steam Methane Reforming (SMR):

The next phase of blue hydrogen production is the core stage, known as the steam methane reforming process. Here, methane from natural gas is exposed to high-temperature steam, creating a chemical reaction resulting in two primary outputs: - Hydrogen gas:

The hydrogen produced in this step is the end product engineers aim to achieve, as it is rich in energy and versatile for various applications. - Carbon monoxide:

Earlier in the piece, we mentioned how carbon dioxide is a byproduct of blue hydrogen - which it is. However, carbon monoxide is first formed before turning into the final byproduct of carbon dioxide. Our next point further explains this. - Water-gas shift reaction:

For engineers to achieve optimal yields of hydrogen while reducing the carbon footprint, the carbon monoxide produced in the early stages of the process is subjected to the water-gas shift reaction. Here, additional steam is introduced to transform carbon monoxide into increased hydrogen and carbon dioxide levels. This step enhances the overall efficiency of the process, converting the potential waste of carbon monoxide into usable hydrogen and carbon dioxide. - Carbon Capture and Storage (CCS):

A defining feature that sets blue hydrogen apart from conventional methods is the integration of carbon capture and storage (CCS) technologies. Due to the environmental concerns associated with carbon dioxide emissions, talent working in blue hydrogen production strives to manage these emissions responsibly. CCS systems deployed in the process of blue hydrogen capture the carbon dioxide created during the SMR and water-gas shift reaction.

Once captured, this CO2 can be:

- Stored underground in geological formations

- Repurposed for applications like enhanced oil recovery

- Utilised for other industrial purposes

The benefits of blue hydrogen - how it’s utilised

With its unique combination of traditional production methods and carbon capture and storage technologies, blue hydrogen production presents a versatile and eco-conscious energy solution that you can be a part of by embarking on a career in blue hydrogen. Here's a closer look at the benefits of blue hydrogen and how it's used across diverse sectors:

- Power generation benefits:

One of the primary benefits of blue hydrogen utilisation is its ability to generate power. For example, power plants can leverage blue hydrogen as a fuel source, offering a transitional pathway towards cleaner energy. As blue hydrogen produces fewer emissions, power generation facilities can significantly mitigate their carbon footprint by substituting conventional fossil fuels with blue hydrogen, contributing to broader sustainability goals.

- A low-carbon alternative for industrial processes:

The industrial landscape also stands to benefit from the integration of blue hydrogen. Due to the versatility of blue hydrogen, it can be utilised across various industrial processes, from sectors such as chemicals, refining and fertilisers. Its role as a foundational element in these processes emphasises its value as a catalyst for cleaner alternatives to traditional fossil fuels used in industrial operations.

- Supports heating and cooling systems:

Residential and commercial infrastructure can also tap into the advantages of blue hydrogen. Heating and cooling systems, traditionally reliant on fossil fuels, can transition towards blue hydrogen as a more eco-friendly alternative. By doing so, these systems can offer enhanced efficiency and reduced environmental impact, aligning with sustainable building practices.

- Integrates with steel production:

Additionally, the steel industry, often characterised by its substantial carbon emissions, can benefit by adopting blue hydrogen. Blue hydrogen emerges as a viable substitute for coal in the steel-making process. By integrating blue hydrogen into steel production, the industry can realise significant reductions in carbon emissions, paving the way for a more sustainable and responsible approach to steel manufacturing.

The drawbacks of blue hydrogen

While blue hydrogen presents a transitional solution towards a low-carbon energy future, it’s essential to acknowledge its inherent challenges and limitations. Here are the notable drawbacks associated with blue hydrogen production:

- Reliance on non-renewable natural gas:

One fundamental concern surrounding blue hydrogen production is its dependency on natural gas as a primary feedstock. As a non-renewable fossil fuel, these natural gases bring a carbon-intensive element into the process of this type of hydrogen. Although blue hydrogen is categorised as a low-carbon hydrogen, it remains intrinsically tied to carbon-emitting processes due to its association with natural gas.

However, as the world continues to transition to cleaner energy alternatives and has yet to rely solely on renewables as primary power sources, blue energy is still a positive alternative to traditional usage of fossil fuels and a step in the right direction.

- Carbon capture and storage complexities:

Another distinguishing feature of blue hydrogen is the integration of carbon capture and storage technologies. However, the deployment of CCS presents its own technical and economic challenges. These complexities can cause high production costs and introduce safety considerations.

Of course, blue hydrogen is not the only alternative energy facing obstacles. All forms of energy production are met with challenges one way or another. Individuals working in blue hydrogen jobs are continually looking at ways to reduce the costs and technical difficulties involved in this low-carbon energy alternative to fossil fuels.

- Methane leakage concerns:

One final drawback of blue hydrogen production concerns the transportation of methane, an integral part of the process. Transporting this hydrocarbon does carry the risk of methane leakage. As methane is a greenhouse gas, it poses higher threats to global warming potential than carbon dioxide over shorter time frames. If methane is released while producing blue hydrogen, it can undermine the purpose of being a low-carbon alternative energy.

Again, like other alternative energy sources, there is always a risk that production goes wrong. However, this does not mean it happens frequently or intentionally. Talent working in blue hydrogen production operates as efficiently as possible, going above and beyond to mitigate any risks associated with the process and keeping the goal of creating a low-carbon energy alternate at the front of their mind.

What is green hydrogen?

Green hydrogen is an area within the hydrogen space pioneering innovation in the renewable energy industry. At the heart of green hydrogen production lies the electrolysis process, which involves using renewable sources, including hydropower, solar power, or wind energy, to power the electrolysis process. Later in this section, we'll delve into the process of electrolysis.

One of the standout features of green hydrogen production is its impact on the environment. By harnessing renewable energy sources for the electrolysis process, the production of green hydrogen avoids the use of greenhouse gas emissions. As a carbon-neutral approach, green hydrogen is positioned as a viable solution in the fight against climate change, supporting sectors eager to tackle their carbon-intensive practices and transition into cleaner alternative energy.

How is green hydrogen produced?

If you’re considering pursuing the latest green hydrogen jobs, The production of green hydrogen is primarily formed through the process of electrolysis, which involves the passage of an electric current through water. This electrical stimulation creates a chemical reaction within the water molecules, leading to their breakdown into:

- Hydrogen: Produced at the cathode, the negatively charged electrode, this hydrogen serves as the cornerstone of green hydrogen, offering a clean energy alternative with diverse applications.

- Oxygen: Additionally, oxygen is created at the anode, presenting itself as a valuable byproduct with various industrial and environmental uses.

What sets green hydrogen production apart from other energy solutions is its reliance on renewable energy sources for the electrolysis process. Whether it's solar, wind, or hydropower, these sources of clean energy provide the electricity needed to accelerate the electrolysis of water. This symbiotic partnership ensures that the entire production chain of green hydrogen remains devoid of greenhouse gas emissions, reinforcing its stance as a sustainable energy solution.

The benefits of green hydrogen - how it’s utilised

Green hydrogen production has many benefits that reinforce its significance in the renewable energy industry, supporting various sectors eager to support the energy transition. Green hydrogen is being harnessed for diverse applications - applications you can be part of by kickstarting your career with green hydrogen jobs:

- Energy storage and backup power:

One of the most significant benefits of green hydrogen production is its potential as an energy storage medium. Green hydrogen can be stored and subsequently deployed as backup power, which is highly beneficial for instances where power outages occur or in regions with limited access to electricity.

- Fuel for transportation:

The transportation sector can benefit significantly from green hydrogen production. Green hydrogen serves as a clean and efficient energy source to power electric vehicles, from cars, buses and trains. By leaning on green hydrogen, future electric vehicles will see them cover greater distances without the issue of releasing harmful emissions.

- Potential mainstream source of renewable energy:

Green hydrogen's versatility extends to power generation, where it can be channelled to generate electricity on a mainstream level. Households and businesses can harness this renewable energy source as an alternative to fossil fuels to meet their energy needs. The reliability and renewability of green hydrogen will continue to appeal to the masses as a mainstream energy source, allowing people to power their everyday lives with a clear conscience.

- Supports industrial processes:

Similarly to blue hydrogen, the benefits of green hydrogen can support industrial sectors. Green hydrogen can be seamlessly incorporated into various industrial processes, including refining, chemicals, and fertilisers. The key difference here is that green hydrogen is carbon neutral. Later in this piece, we'll summarise the difference between blue hydrogen vs green hydrogen.

The drawbacks of green hydrogen

While green hydrogen production boasts many positives to the future of sustainable energy, it’s not without its challenges:

- High production costs:

As mentioned, green hydrogen production hinges on abundant renewable energy like solar, wind, or hydropower. While these renewable sources are eco-friendly, they often come with substantial upfront infrastructure development and maintenance costs. As a result, the cost of generating green hydrogen can be considerably higher than that of conventional hydrogen production methods.

However, as the world gradually shifts to renewable energy sources to combat climate change and provide an alternative to finite fossil fuels, the production of renewables like green hydrogen will become more frequent and mainstream. As a result, the cost of green hydrogen production will likely decrease in time.

- Limited availability due to intermittency:

One of the inherent characteristics of specific renewables is their intermittent nature. As green hydrogen relies on these energy sources, like solar and wind, this intermittency directly impacts the consistency of green hydrogen production, potentially leading to periods of limited availability. Such unpredictability can pose challenges for industries and sectors reliant on a consistent supply of hydrogen.

Much of this relies on engineers choosing locations where solar panels and onshore and offshore wind turbines operate. As renewable technologies advance and appropriate locations for specific types of renewable sources are considered, green hydrogen production can thrive and overcome the drawbacks surrounding limited availability due to intermittency.

- Infrastructure challenges:

The green hydrogen production value chain, encompassing transportation and storage, necessitates a robust and extensive infrastructure network. Building out this infrastructure is a multifaceted endeavour, requiring substantial investments of time and capital. The complexities associated with infrastructure development and the logistical considerations of transporting and storing hydrogen can introduce additional layers of complexity and cost into the green hydrogen space.

Again, as more investment is given to the renewable energy industry and alternative power sources grow in popularity, the costs and logistics of developing infrastructure for green hydrogen production will see a gradual decrease.

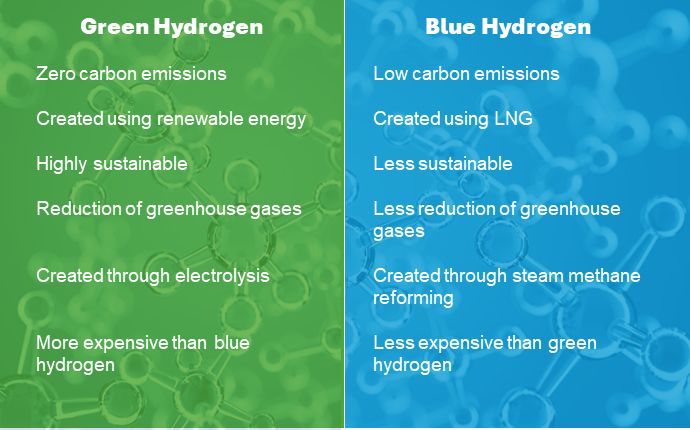

Blue hydrogen vs green hydrogen: Summarising the differences

Blue and green hydrogen have the potential key to be players in the transition to low-carbon and sustainable energy solutions. While both aim to reduce carbon emissions associated with traditional hydrogen production methods, they differ significantly in their production processes and environmental impacts.

In terms of environmental impact, green hydrogen boasts a lower carbon footprint since it's produced entirely from renewable energy sources. Its production does not contribute to greenhouse gas emissions, aligning with global sustainability goals. With blue hydrogen production, there is still some reliance on fossil fuels. However, integrating carbon capture and storage technologies makes it a transitional solution, offering a low-carbon energy solution to traditional hydrogen production methods.

Both green and blue hydrogen present economic opportunities. For example, with its zero-emission and connections with other renewable energy sources, green hydrogen is seen as a long-term sustainable solution but requires significant investment in renewable infrastructure. Blue hydrogen, on the other hand, leverages existing natural gas infrastructure, potentially offering a more cost-effective transitionary solution while supporting job retention in the fossil fuel sector.

The debate between green and blue hydrogen often centres on their respective roles in the energy transition. Some argue for a combined approach, utilising blue hydrogen as a bridge while scaling up green hydrogen infrastructure. Others emphasise a faster shift towards green hydrogen to maximise environmental benefits.

While there is a distinct difference between blue and green hydrogen, they both represent pathways to a decarbonised future, contributing to reducing carbon intensity in the energy sector. The choice between green and blue hydrogen depends on various factors, including technological advancements, economic considerations, and environmental priorities.

You also have a choice regarding which avenue to pursue regarding a career via blue and green hydrogen jobs. From engineering roles to project management, sales and financing, there are various routes you can take to impact the global energy transition.

Considering a career in renewables? Discover our guide to the top 5 most searched alternative and renewable energy jobs.

Looking to grow in the renewable energy industry?

If you're looking to register for the latest blue and green hydrogen jobs to power your career in renewable energy, we can help. As a global leader with over two decades in the renewable energy recruitment space, we can connect you with the market's top opportunities for the world's leading innovators.

Alternatively, contact us today for more support on how we can help progress your renewable energy career in green and blue hydrogen.